Manufacturing Market News and Your Strategic Plan

The US manufacturing industry is in a period of profound uncertainty. We have experienced discord from new tariffs, ongoing inflation and a complexity of sectoral strengths and weaknesses (Feimster, 2025). Companies have had to adapt to ongoing volatility in the marketplace. This has meant flexibility and sometimes pivoting in terms of pricing and supply chain strategies (Feimster, 2025). Firms are quickly moving to mitigate risk and to stay competitive. Some are mandating domestic and even regional material hubs and are implementing tariff escalation clauses within their new contractual agreements. Companies are also investing in AI-driven estimating tools to manage pricing (Steel Industry News, 2025).

According to the National Association of Manufacturers (2025), while September factory production rose as new orders came in, inventory levels remain high due to weak sales growth. Supplier delivery times were the highest within the past four months. Weak demand and growing competition have caused prices to level off for many sectors. Tariffs were again overwhelmingly cited as the principal cause of further cost increases in September.

Overall business activity slowed to a three-month low, falling from 54.6 in August to 53.6 in September. New order growth also slowed despite exports rising for the first time since March of this year (NAM, 2025). Some estimate that inflation will increase to 3.3% (from 2.3%) if current tariffs remain in place (Nassauer, Whalen and Pacheco, 2025).

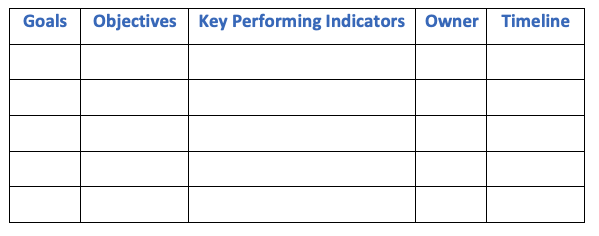

We are already in the fourth quarter of 2025. It’s not too early to be thinking about 2026. This is may be an ideal time for your leadership to develop a new strategic plan. A well-constructed strategic plan will help manufacturing leaders consider their organization in a broader context for informed and long-term decision-making and communications. Well-chosen key performing indicators will guide implementation.

Understanding Manufacturing Key Performing Indicators

Manufacturing KPIs measure the performance of production processes in relation to strategic business objectives. These indicators provide manufacturers with objective, data-driven insights that enable them to track operational efficiently, and support continuous improvement initiatives. While KPIs are common across industries, manufacturing-specific indicators focus on key areas such as:

- Production Efficiency

- Quality Control

- Equipment Effectiveness

- Supply Chain Performance

(Note: Though often used interchangeably, metrics and KPIs are not the same. Metrics are fundamental data points about processes or activities, such as units produced or machine run times. KPIs are a carefully chosen list of designators that businesses use as strategic indicators by directly tying them to predetermined targets.)

Manufacturers can use identified KPI’s to uncover bottlenecks, reduce material waste, optimize the use of labor and equipment, and align production activities with overarching business goals (Jenkins, 2025).

What is the best way for a company to monitor their strategic plan for optimal implementation?

A strategic plan for your manufacturing company should consider goals, objectives, key performing indicators and results, or OKR’s. OKRs help organizations and teams define and align around their most important outcomes for a fixed time period (Grove, 1983).

No one wants a strategic plan to end up collecting dust on a bookshelf. A well-done strategic plan should be a working document that reinforces your organization’s core foundation and operational excellence, while providing the opportunity to consider new innovations, ultimately making your organization more competitive in the industrial landscape.

Contact us today to learn more about strategic planning for your manufacturing company!

This article or any other promotional material(s) from Woodland Strategies, Inc. is in no way intended to be a comprehensive plan.

Please note all markets, circumstances, and results vary. Any strategic plan or marketing initiatives must follow all State and Federal laws and regulations, accordingly.

Please contact us directly for a complete assessment and plan for your individual organizational needs.